Quality Made In Italy

100% of the machine components are produced in Italy.

Bieffe has been cooperating with the best Italian suppliers for many years. The boilers and resistors, the most important components of the machines, are produced internally under strict control.

The assembly of all machines is carried out within the Bieffe company, located in Pesaro, Italy. All products are checked after assembly to ensure their correct operation. From Italy, the finished products are shipped to more than 30 countries worldwide.

The machinery has a high repairability index and is manufactured through sustainable business processes.

98% of products are made from recyclable materials such as copper, steel, and aluminum.

Perché scegliere Macchine a Vapore BIEFFE

- Reliability and Safety

- Guaranteed Accessories and Spare Parts

- Cleaning and Sanitization certified by laboratories

- Very fast telephone assistance

- The entire production takes place in Italy, in our Pesaro factory

- For over 30 years we have been producing steam generators, with over 500,000 machines sold worldwide

- With 1 kW of power, our machines generate a steam flow rate of 1.3 kg/hour. It’s important to keep in mind that the effectiveness of steam is proportional to its flow rate, not its pressure.

Safe and durable products.

Copper boilers

The boiler is made of copper, an explosion-proof material (it cannot explode and, in the event of a possible breakage, it does not suffer a loss of components).

External resistors

The resistors are external to the boiler, therefore, being not in contact with water, they cannot be corroded by limescale.

Teflon fittings

The electromechanical components are assembled without glue. A Teflon wrap is used for the fittings. All machine components can be easily disassembled and replaced.

In a world where sustainability is at the heart of conscious choices, Bieffe Farinelli stands out for the high repairability index of its products. This means that our devices are designed to be easily repaired, reducing waste and extending the useful life of the appliances.

We offer spare parts at affordable prices, quickly and always available for many years; instruction manuals and dedicated assistance to facilitate repairs. Choosing our products not only benefits the environment, but also protects your long-term investment.

Bieffe Farinelli machinery is manufactured through sustainable business processes. Made from 98% recyclable materials such as copper, steel, and aluminum.

Quality control

During assembly, all Bieffe machines are scrupulously checked and tested, as are all its spare parts. This guarantees safety, high quality and durability over time.

Available spare parts

Bieffe always adapts to the customer’s preferences and does not use components of particular manufacture, so that all spare parts can be easily found on the market.

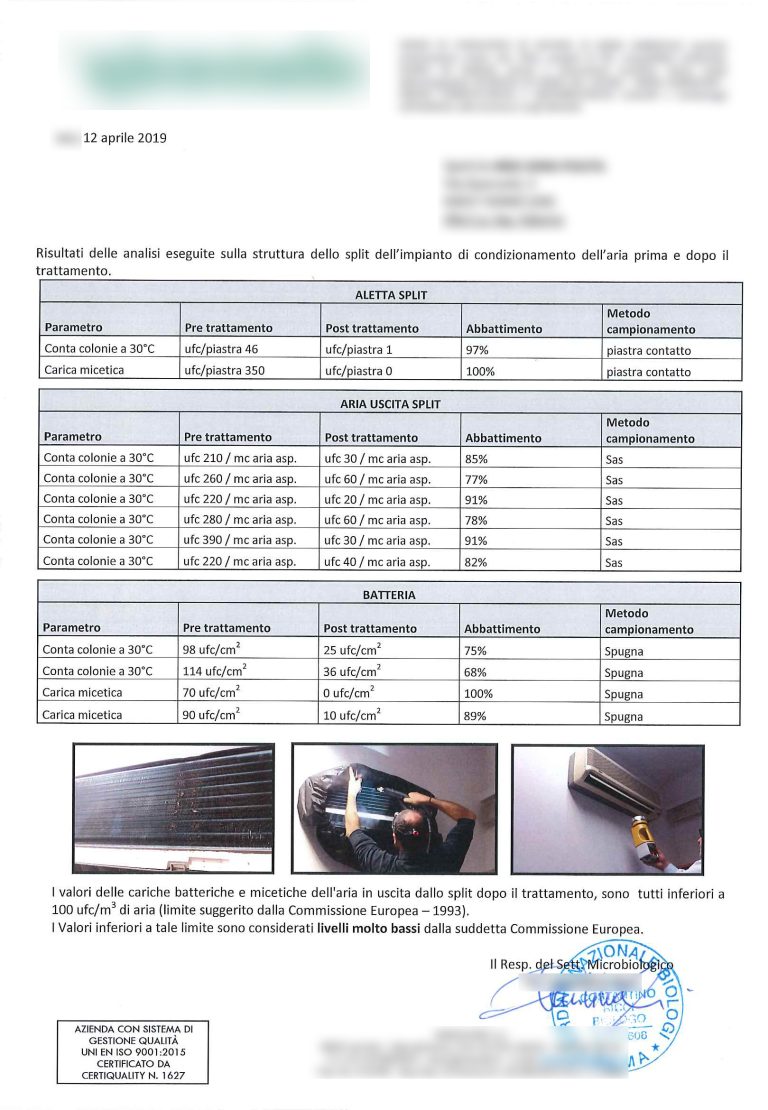

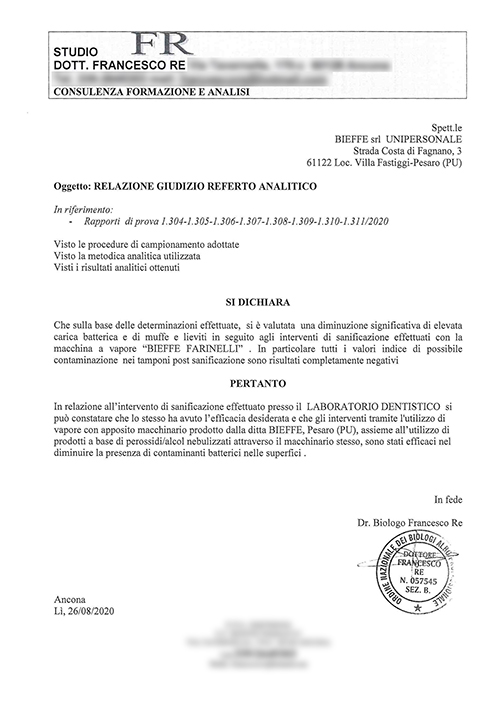

Steam efficacy proven by laboratories

Analysis performed on Ariasana

The effectiveness of the sanitization of Ariasana, a specific machine for the cleaning and sanitization of air conditioners, has been proven by scientific tests that confirm the reduction of bacteria.

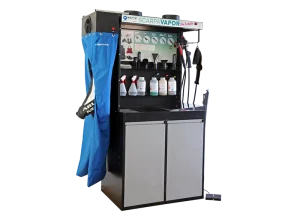

The effectiveness of our steam against dirt and bacteria

The effectiveness of our steam machines has been proven by scientific analyses carried out by accredited analysis laboratories. Saturated steam at 165°C or 180°C, combined with disinfectants, is still one of the most effective and economical methods for sanitizing surfaces. Some of our steam sanitizing systems do not need rinsing and leave no streaks. Discover MAGIC VAPOR SANI, a machine that combines the power of steam with disinfectants, creating a mist that envelops the surface for rapid sanitization without rinsing.

Ecology

Steam, used in the early 1800s to develop mechanical energy, is then rediscovered as a source of economical cleaning.

Steam continues to trigger new behavioral and cultural processes by combining ecology, economy, safety and health.

The keys to its success are unparalleled cleaning and sanitizing effectiveness, combined with a reduction in energy consumption and the use of detergents.

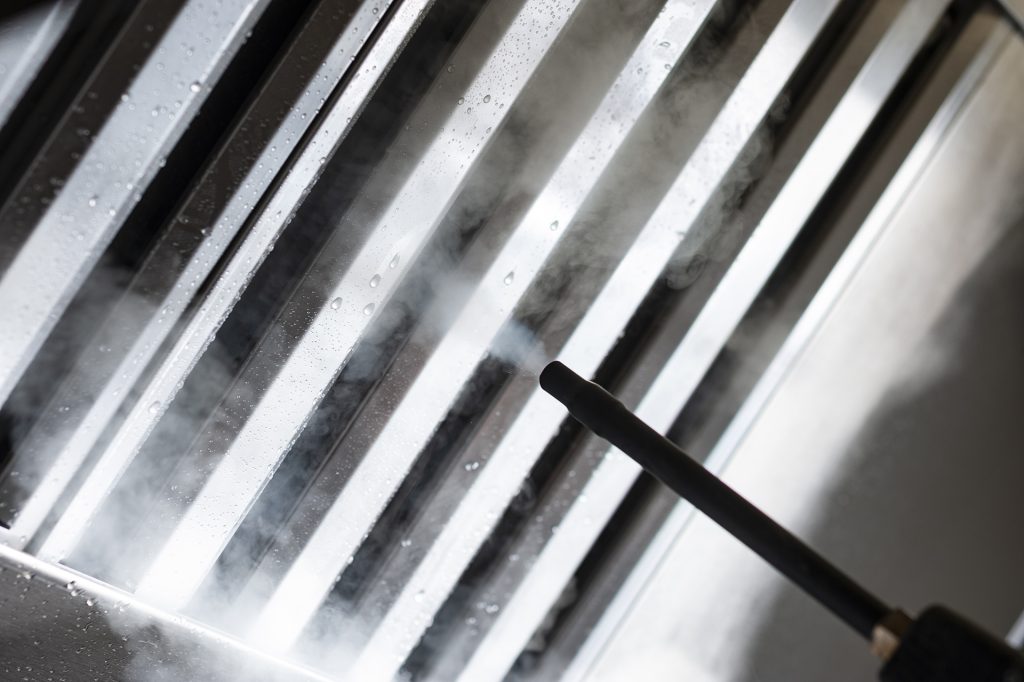

The dry steam technology

This involves the principle of dry steam, brought to a temperature of between 120 and 170°C. At this temperature, the steam releases incredible power that fights deep dirt and micro-organisms without damaging the environment and fabrics.

Dry steam works thanks to three factors:

- the temperature, which is the main one,

- residual micro humidity, which acts as a solvent and retains dust residues,

- the pressure, which increases the cleaning effectiveness in depth.

The pressure and high temperature annihilate microbes, bacteria and the most common allergens, averting the risk of allergies and other pathologies connected to the use of chemical detergents.

A healthy and sustainable future.

Steam cleaning does not require additional chemicals, which benefits those who are sensitive to chemicals or want to reduce the level of toxicity in their homes, especially when children are present.

Steam cleaning reduces water consumption compared to other cleaning methods (it is estimated that 1000 liters of steam are produced for every liter of water) and does not involve the use of any chemical detergents.